Shipyard Transporters Revolutionizing Shipbuilding Logistics

Get Latest Price| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF |

| Transportation: | Ocean,Land |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF |

| Transportation: | Ocean,Land |

| Selling Units | : | Others |

Shipyard Transporters: Revolutionizing Shipbuilding Logistics

Shipyard transporters, serving as self-propelled heavy-duty hydraulic trailers (transporters), are instrumental in the shipbuilding industry. They are specifically designed to handle immense loads ranging from 50T to 1000T, which is crucial for transporting large ship sections, engines, and other significant components within shipyards. This article elaborates on their advanced features and the pivotal role they play in modern shipbuilding.

Advanced Power and Steering Systems

A key element of the Shipyard Transporter is its sophisticated power system, which comprises a DA variable displacement pump, hydraulic motor, control valves, sensors, and electric control components. This system ensures reliable and efficient operation, crucial for handling heavy loads.

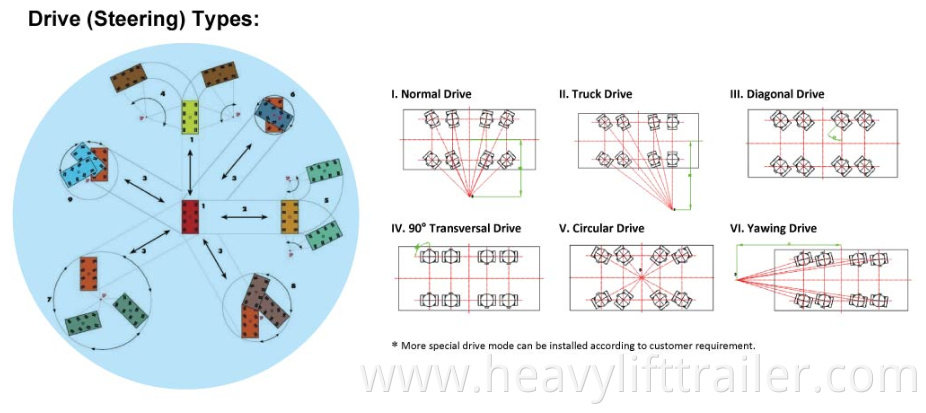

The transporter’s steering system is another marvel. It features independent, computer-controlled steering powered by cylinders. This system allows for a variety of steering modes, including normal, circular, and angled steering, enhancing maneuverability and precision in tight shipyard spaces.

Innovative Design for Enhanced Maneuverability and Precision

Ensuring Precision and Safety

Precision in movement and elevation is further guaranteed by angular and speed sensors. These sensors are integral for accurate placement of ship parts, a critical aspect of ship assembly. The transporter's ability to execute sensitive and precise maneuvers is not just a matter of efficiency, but also a significant safety factor, reducing the risk of accidents in the shipyard.

The Future of Shipyard Transport

With their exceptional load capacity, advanced steering technology, and high maneuverability, shipyard transporters are set to continue playing a vital role in the shipbuilding industry. Their ability to transport huge components with precision and safety is indispensable in modern shipyards, contributing significantly to the efficiency and effectiveness of ship construction and assembly processes.

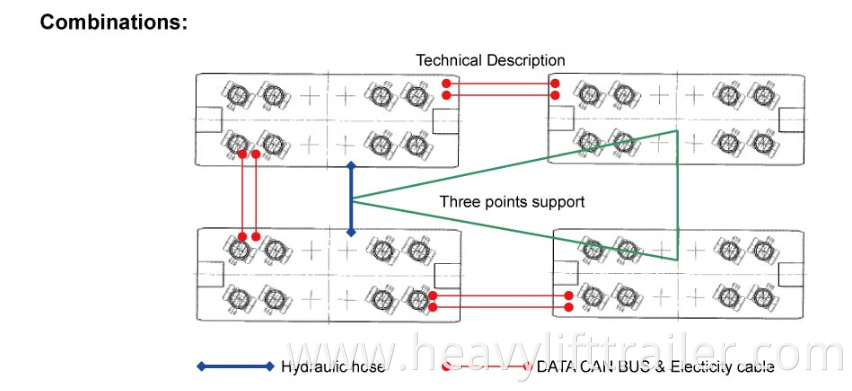

Steering and combination

The below design are for 2 to 10 axle line shipyard transporter: every axle line consists of two sets of suspension and axles, if adopt 32tons axle and suspension, then the capacity of each axle line is 64tons; if adopt 16tons suspension and axle, then the capacity of each axle line is 32ton. 2 to 10 axle lines can transport cargo from 50tons to 500tons. For more capacity, more quantity of axle line, more powerful engine and pump can do the job.

Shipyard transporter main specification list

| Model | Dead weight (ton) | Loading capacity (ton) | Length x width(mm) | Height (mm) | Suspension/Axle lines | Driving axle | Brake axle | Speed (empty load) | Speed (full load) | Loading capacity per axle(ton) |

| 75A | 24 | 72 | 11000X5000 | 1400+600 | 6/3 | 3 | 3 | 5km/h | 10km/h | 16 |

| 100A | 28 | 100 | 12000X5000 | 1400+600 | 8/4 | 4 | 4 | 5km/h | 10km/h | 16 |

| 125A | 32 | 125 | 14000X5000 | 1400+600 | 10/5 | 4 | 6 | 5km/h | 10km/h | 16 |

| 150A | 36 | 150 | 15800X5000 | 1400+600 | 12/6 | 5 | 6 | 5km/h | 10km/h | 16 |

| 175A | 41 | 175 | 19600X5000 | 1400+600 | 14/7 | 5 | 8 | 5km/h | 10km/h | 16 |

| 200A | 48 | 200 | 22000X5000 | 1400+600 | 16/8 | 6 | 10 | 5km/h | 10km/h | 16 |

| 100B | 24 | 100 | 10000X5100 | 1600+700 | 4/2 | 2 | 2 | 5km/h | 10km/h | 32 |

| 150B | 36 | 150 | 12000X5100 | 1600+700 | 6/3 | 2 | 4 | 5km/h | 10km/h | 32 |

| 200B | 43 | 200 | 14000X5100 | 1600+700 | 8/4 | 3 | 4 | 5km/h | 10km/h | 32 |

| 250B | 52 | 250 | 16000X6100 | 1600+700 | 10/5 | 4 | 6 | 5km/h | 10km/h | 32 |

| 320B | 60 | 320 | 18000X6100 | 1600+700 | 12/6 | 4 | 8 | 5km/h | 10km/h | 32 |

| 380B | 68 | 380 | 20000X6100 | 1600+700 | 14/7 | 5 | 8 | 5km/h | 10km/h | 32 |

| 420B | 85 | 420 | 22000X6100 | 1600+700 | 16/8 | 5 | 10 | 5km/h | 10km/h | 32 |

| 480B | 94 | 480 | 24000X6100 | 1600+700 | 18/9 | 6 | 12 | 5km/h | 10km/h | 32 |

| 530B | 110 | 530 | 26000X6100 | 1600+700 | 20/10 | 6 | 12 | 5km/h | 10km/h | 32 |

| 580B | 124 | 580 | 28000X6100 | 1600+700 | 22/11 | 7 | 14 | 5km/h | 10km/h | 32 |

| 630B | 135 | 630 | 32000X6100 | 1600+700 | 24/12 | 8 | 14 | 5km/h | 10km/h | 32 |

| 680B | 148 | 148 | 34000X6100 | 1600+700 | 26/13 | 8 | 16 | 5km/h | 10km/h | 32 |

| All of model grade ability is 6%. Width of 100B, 150B and 200B is 5100-6100mm and other dimension needs to be customized. | ||||||||||

Main parts

The main pars and componets equipped to the shipyard transporter, such as suspension, axle, automatic control system, hydraulic system, are strictly selected and purchased from reliable overseas and domestic reliable brands of mature technology. For example, the automatic system adopts complete technology and parts of German Rexroth, avoids problems like bad compatibility caused by non-uniform of different parts and technology and reduces risk in R&D of new products and guarantees the stability and reliability of performance.

| Itme name | Brand | Country |

| Engine | Commins / Deuta | America / Germany |

| Drive pump | Rexroth / Sauer | Germany |

| Turning and lift pump | Rexroth / Sauer | Germany |

| Retarder | Recroth / RR | Germany / Italy |

| Motor | Rexroth / Sauer | Germany |

| Valve | Hawe / Rexroth | Germany |

| Control system | Interconcrol / Rexroth | Germany |

| Torsional damping aggangement | KTR | Germany |

| Cooler | AKG | Germany |

| Filter | Argo | Germany |

| Tube union | Eaton | America |

| Rubber duct | Sunflex | Italy |

| Oil cylinder | Hengli | China |

| Slew axletree | FLT | China |

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.