Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

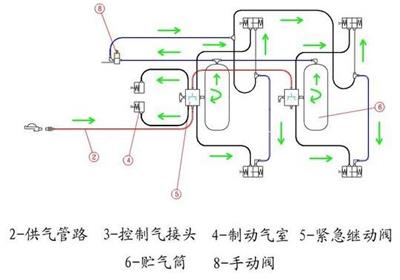

At present, the semi-trailer produced in China adopts double pipe design. In the figure, ①blue line is the control pipeline, ②red line is the air supply pipeline, which is connected to the tractor through ③control air connector.

Via ②air supply pipeline, the tractor goes through ⑤emergency relay valve and supplies air to ⑥air reservoir and parking brake cylinder through ⑧manual valve. At this time, the air pressure of the air reservoir during parking brake is 0bar, which is equivalent to the parking brake state. When the air reservoir exceeds 4bar, the parking brake is released.

When the brake pedal is pressed, the air passes through the ①control pipeline. And at this time, the ⑤emergency relay valve supplies the air from the ⑥air reservoir to the ④brake cylinder of each shaft. The air pressure inside decreases. After receiving the command, the air from the air reservoir will be discharged, and the vehicle starts braking and enters into the braking state again.

The emergency relay valve is the core component of the whole trailer braking system. It is compatible with multiple functions of relay valve, distribution valve, one-way valve and quick release valve. The trailer equipped with emergency relay valve can greatly shorten the braking lag time of the trailer. In fact, the functions of the emergency brake valve are more than these. It has three major functions:

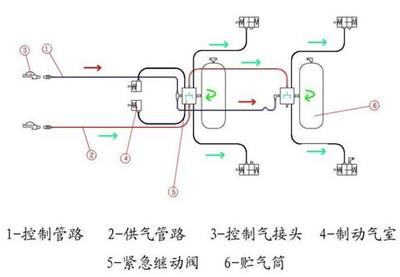

1. Working braking status in normal braking

When the brake pedal is depressed, the ①control pipeline supplies air to the ⑤emergency relay valve, and the ⑤emergency relay valve controls ⑥air reservoir to supply air to ④brake wheel cylinder to generate braking force. When the brake pedal is released, the emergency relay valve quickly releases the compressed air of each sub cylinder and quickly releases the braking state.

2. Feedback braking status during inflation

When the trailer is parked for a long time and there is no air pressure in the brake system, the parking brake system (air cut-off brake) works. When the tractor inflates the ⑥air reservoir of the trailer through the ②air supply pipeline, the emergency relay valve is in the safe braking state at this time.

In the safe state, ⑤emergency relay valve sends compressed air to each ④brake cylinder first. When the air pressure of trailer`s ⑥air reservoir rises to 4.5bar, the safe state is released. This function is referred to as feedback braking function for short. The brake wheel cylinder generates braking force under inflation, which is a safety protection function.

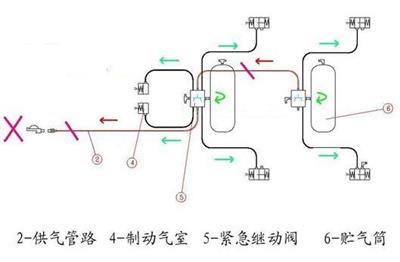

3. Automatic braking state in case of emergency air cut-off fault

When the ②air supply pipeline is accidentally damaged during driving, the compressed air in the ⑥air reservoir of the trailer enters the ④brake cylinder through the ⑤emergency relay valve to automatically implement braking measures to ensure the safety of the vehicle in case of emergency. It can drive to the maintenance place in a short time, but it will not last too long. When the tractor stops, it`s necessary to disconnect the ②air supply pipeline of the trailer. It can also be seen that the trailer brake cylinder works, which is the same principle.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.