Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Basic requirements met by the braking system of a semi-trailer

ABS braking performance test

The braking system design of semi-trailer has mandatory rigid requirements. Due to the special articulation characteristics of traction semi-trailer, while satisfying the basic conditions of vehicle deceleration, parking and other functions, the following requirements must also be met:

1. The relevance of the braking system between the trailer and the tractor, and the braking action works in coordination with each other.

2. The sequence coordination between the trailer and the tractor braking system, the order of braking action is the tractor front wheel, the semi-trailer wheel, and the tractor rear wheel to ensure the stability of the vehicle.

3. When the trailer is disengaged from the tractor, the brake pipeline is cut off; or the trailer pipeline is broken or damaged in an emergency, the trailer brake system automatically brakes to ensure safety. (Note that this is not a simple sense of the stop brake work)

4. When the car and train are fully loaded, the towing state ensures safe and reliable parking on 16% of the ramps; the trailer must be additionally equipped with a parking brake system to ensure the braking state when parked when it is separated from the tractor alone.

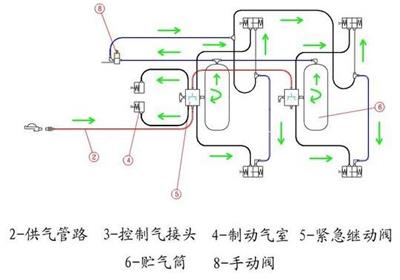

Diagram of Brake Air Circuit Layout for Semi-trailer

At present, domestically produced semi-trailers adopt a dual-pipe design. ① is the control pipe and ② is the control pipe, which is connected to the tractor through the ③ control gas connector. The actual common air supply pipe corresponding to the vehicle is a red spiral pipe. The control pipeline is generally yellow or blue spiral tube.

1. Gas supply pipeline

The tractor supplies air to the air reservoir through the ② air supply pipeline through the ⑤ emergency relay valve, and at the same time supplies air to the parking brake cylinder (the part of the parking chamber of the brake cylinder) through the manual valve ⑧. When the air reservoir exceeds 4 bar, the parking brake is released.

2. Control pipeline When the brake pedal is stepped on, ① the air in the control pipeline is over, and the emergency relay valve is top opened. At this time, the gas reservoir starts to supply air to the brake cylinders of each axis, and the vehicle starts to brake. Enter the braking state. ...

The important role of emergency relay valve

Emergency relay valve

The emergency relay valve is the core component of the entire trailer braking system. It is compatible with multiple functions of relay valve, distribution valve, one-way valve, and quick release valve. The trailer equipped with emergency relay valve greatly shortens the lag time of trailer braking. . In fact, the emergency brake valve has more than these functions. It has three major functions:

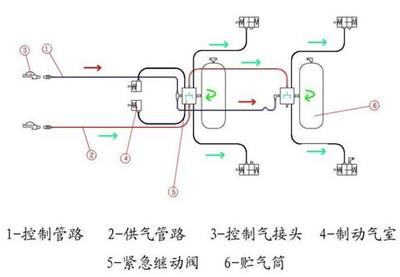

1. Working braking state in normal braking

Schematic diagram of emergency relay valve working brake

This is the most direct function we feel. When the brake pedal is stepped on, the control pipeline ① delivers air, and the emergency relay valve ⑤ controls ⑥ the air cylinder to supply air to the brake cylinder to generate braking force; when the brake pedal is released, The emergency relay valve quickly releases the compressed air of each sub-cylinder and quickly releases the brake state.

2. Feedback braking state during inflationWhen the trailer is parked for a long time and the brake system has no air pressure, the trailer parking brake system (air brake) will work. When the tractor is inflated into the air cylinder of the trailer ⑥ through the gas supply pipeline, the emergency relay valve is now in a safe braking state.

In the safe state, the emergency relay valve sends compressed air to each brake cylinder. When the air pressure of the trailer ⑥ air cylinder rises to 4.5 bar, the safe state is released. This function is referred to as feedback braking function. The brake cylinder generates braking force in the inflated state, which is a safety protection function.

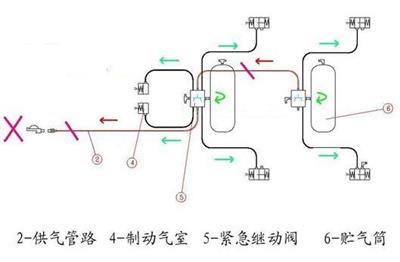

Automatic braking state in case of emergency air failure

When ② the air supply pipeline is accidentally damaged, the compressed air in the trailer ⑥ air tank will enter the ④ brake cylinder through the ⑤ emergency relay valve to automatically implement braking measures to ensure the safety of the vehicle in an emergency. When the tractor is stopped and the trailer ② gas supply pipeline needs to be disconnected, the trailer brake cylinder can also be seen to work, which is the same principle.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.